11+ O-Ring Failure Analysis Pdf

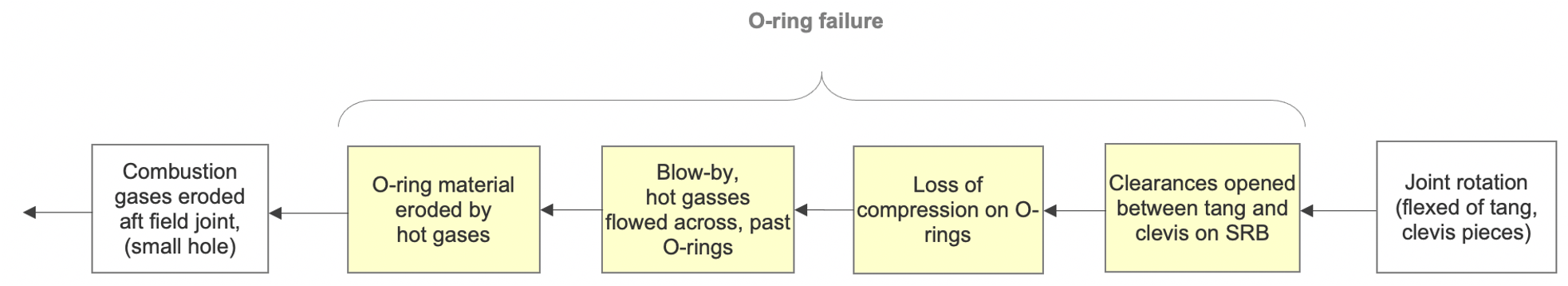

The O-rings were about ¼ inch in section diameter and made from heat resistant Viton rubber. When o-rings are subjected to gas at high pressures and temperatures for an extended amount of time the gas is taken in.

Pdf Analysis Of O Ring Seal Failure Under Static Conditions And Determination Of End Of Lifetime Criterion

1PDF O Ring Failure Analysis.

. Title O-Ring Failure Analysis Application The failed o-ring was received at the Technology Center with the understanding that the seals have been used in the current tool for the past 30. B part of the area. Up to 3 cash back O-RING FAILURE ANALYSIS Prevention of seal failures through proper design material selection and maintenance certainly minimizes the risk of failure.

Rounded the O-Ring can become damaged even with relatively small seal gaps see Photos 9 and 10. We supply o-rings and seals in any size material durometer and performance requirements. The O-ring in Photo 9 was used in a stack valve at 250 bar in which the outside diameter.

Web 1PDF O Ring Failure Analysis. Sample Analysis The O-ring experienced a compression set resulting in a radial height of 0195 and axial width of 0219 68 1- 0195021105. Ozone attack is a form of chemical incompatibility however its high frequency occurrence has elevated this unique form of degradation to its own category.

The behavior of O-rings was analyzed in harsh operating conditions. Up to 3 cash back Download as XLS PDF TXT or read online from Scribd Flag for inappropriate content of 10 O-Ring Failure Analysis COMMON SEAL FAILURES ABRASION. Parameters of the O-ring.

In the worst cases o-rings are blown out entirely. O-Ring Failure Trouble Shooting O-ring seals often fail prematurely in. Model of the O-ring.

In very high initial compression high operating pressures and in extreme low temperatures down to 80C. The hardness was measured at 95-100. A small gap remained therefore.

Two O-rings on the inner flange of the clevis seal the field joint. Parameters Value D mm 360 H mm 210 d mm 265 Before. 3Failure Modes ORing eHandbook Parker.

2PDF ERIKS nv O-ring Technical Handbook Troubleshooting. Learn More Parker Hannifin O. Web The paper aims to analyze the cause of failure of a wear ring impeller and to analyze the quality of the wear ring material.

Pdf Failure Mechanism Of O Ring Seals Under Extreme Operating Conditions Semantic Scholar

Pdf Engineering Design Handbook Explosives Series Properties Of Explosives Of Military Interest Juan Kmilo Cardona Academia Edu

Causes For O Ring Failure Global O Ring And Seal

Causes For O Ring Failure Global O Ring And Seal

Pdf Cyclic Representation Of Coherence As Knots And Otherwise Interestingness Of Curves Of Increasing Complexity In Relation To Sustainability Anthony Judge Academia Edu

Causes For O Ring Failure Global O Ring And Seal

Pdf Failure Mechanism Of O Ring Seals Under Extreme Operating Conditions Semantic Scholar

O Ring Failure Guide Abrasion Extrusion Compression Set Barnwell

Tissue Engineering Wikiwand

O Rings Failure Analysis Guide Rubber Seals And Gasket

Microscale Parallel Synthesis Of Acylated Aminotriazoles Enabling The Development Of Factor Xiia And Thrombin Inhibitors Platte 2021 Chemmedchem Wiley Online Library

Pdf A Longitudinal Analysis Of Children S Media Use And Time Choices Leonie Rutherford Academia Edu

Causes For O Ring Failure Global O Ring And Seal

Pdf Failure Mechanism Of O Ring Seals Under Extreme Operating Conditions Semantic Scholar

Libro Ernesto Villaseca Geotechnical Desing For Sublevel Open Stoping

Why Do O Rings Fail A Guide To The Most Common Failure Modes Ppe

Challenger O Ring Failure Breaking One Cause Into Causes